DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry with their advanced printing capabilities. This innovative method allows businesses to create intricate designs that are not only vibrant but also durable, appealing to the increasing demand for personalized products. Leveraging the benefits of DTF printing, such as reduced costs and versatile application on various fabrics, more brands are transitioning to this technology for their production needs. In this guide, we will delve into the multiple advantages of DTF transfers and highlight how they can elevate your custom apparel offerings. Discover the transformative potential of Direct-to-Film technology and how it can unlock new possibilities in your business.

When we discuss Direct-to-Film transfers, we are referring to a cutting-edge printing technique that stands apart from traditional methods. This process, often hailed for its efficiency, utilizes film to transfer detailed graphics onto fabric, making it an ideal choice for customized clothing items. As we explore the realm of DTF printing, you’ll discover how this technology integrates seamlessly into modern fashion production, offering significant benefits such as vibrant outputs and cost-effectiveness. Additionally, the distinct advantages of using DTF technology will become evident, laying a foundation for innovation in the custom apparel market. Join us as we uncover the essentials of this advanced printing solution and its impact on creative apparel design.

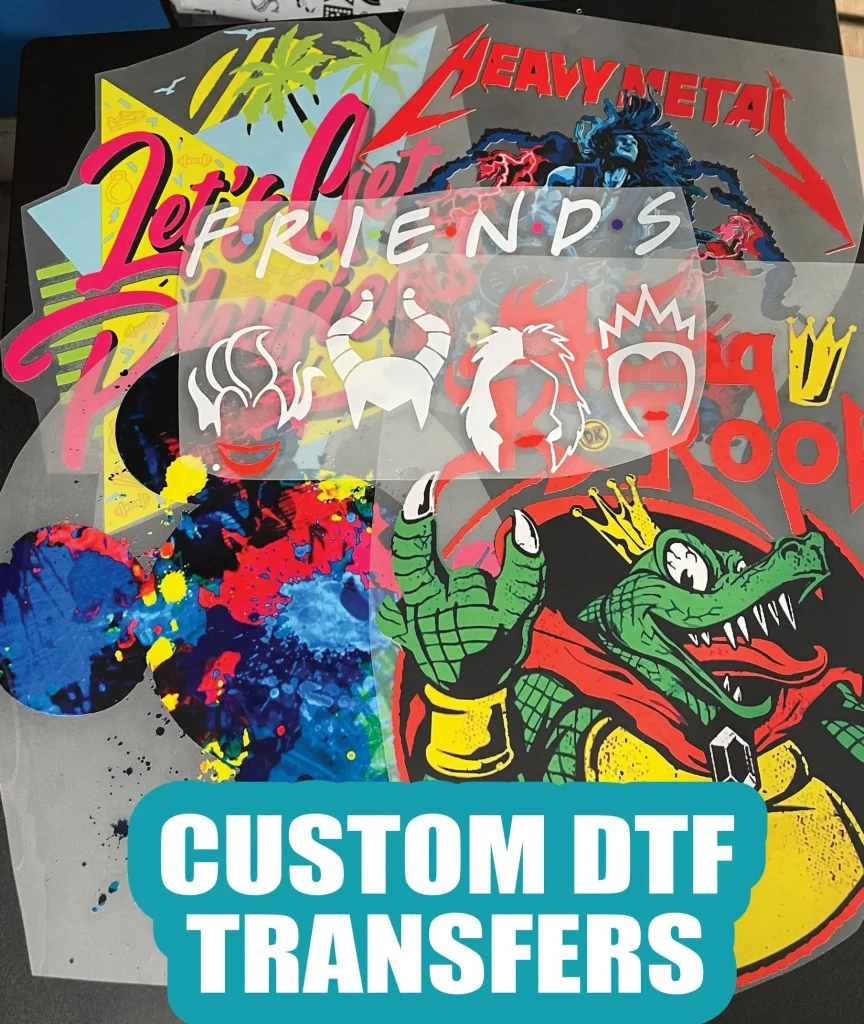

What Makes DTF Transfers the Future of Custom Apparel?

DTF transfers stand out as a revolutionary technology in the realm of custom apparel manufacturing. One of the primary features is their ability to produce high-quality prints that maintain vibrant colors and intricate details over time. Unlike traditional printing methods, which often struggle when dealing with complex designs, DTF printing employs a process that preserves every nuance of an artwork. This ensures that even the most detailed graphics, including gradients and subtle shading, can be reproduced with stunning clarity on various fabrics.

Moreover, DTF technology allows for a range of materials to be used, making it incredibly versatile. Whether you’re working with jersey knits, fleece, or even synthetic blends, DTF transfers can adapt seamlessly. This flexibility not only benefits individual designers looking to specialize in niche markets but also larger businesses aiming to cater to diverse consumer needs. With DTF transfers, the possibilities for custom apparel are practically limitless.

DTF Printing Benefits for Small Businesses

For small businesses operating in the custom apparel market, DTF printing presents numerous benefits that can significantly enhance efficiency and profitability. One notable advantage is the reduced cost associated with short runs and personalized orders. Since DTF transfers require less initial investment in equipment compared to methods like screen printing, small businesses can launch new designs without prohibitive upfront costs. This democratization of high-quality printing technology empowers entrepreneurs to experiment with their product lines more freely.

Furthermore, the durability of DTF prints means that businesses can confidently provide customers with high-quality products that withstand the test of time. This aspect not only enhances customer satisfaction but also promotes brand loyalty, as clients are more likely to return for repeat purchases when they are pleased with the longevity of their apparel. Consequently, the integration of DTF transfers can create a sustainable competitive edge for small businesses in a bustling custom apparel market.

The Latest in DTF Printing Technology

The landscape of DTF printing technology is constantly evolving, driven by innovative advancements that continually improve the printing process. Recent developments include specialized printers that incorporate advanced ink systems designed to enhance color saturation and print longevity. These new devices are typically more compact and user-friendly, making them accessible to both small businesses and enthusiasts, ultimately lowering the barrier to entry for those looking to explore DTF printing.

In addition, the introduction of lightweight adhesive powders has transformed DTF transfers. These innovative materials not only strengthen the bond between the transfer and the fabric but also minimize bulk, ensuring that the printed design maintains the natural feel of the garment. Such advancements illustrate a commitment to improving user experience and resulting product quality, reinforcing DTF technology as a frontrunner in the custom apparel printing landscape.

Understanding the Market Trends in DTF Printing

As consumer preferences shift towards personalization and quick turnaround times, DTF printing is becoming a cornerstone of the custom apparel market. Reports highlight that businesses are increasingly gravitating towards this technology to meet the demands of an on-demand economy. With e-commerce flourishing, DTF printing enables businesses to offer customized products with fast fulfillment, a critical factor for maintaining customer satisfaction in the digital marketplace.

Furthermore, sustainability trends are shaping the DTF printing landscape as manufacturers deploy eco-friendly inks and sustainable practices. Consumers are becoming more environmentally conscious, prompting businesses to adapt to these preferences. Companies that harness the power of sustainable DTF printing not only enhance their brand’s image but also position themselves favorably in a competitive market that prioritizes environmental responsibility.

Step-by-Step Guide to Getting Started with DTF Transfers

Embarking on your DTF printing journey can feel daunting, but numerous resources exist to simplify the process. Many comprehensive guides provide detailed instructions covering everything from choosing the right printer to mastering heat-pressing techniques. These resources typically emphasize the importance of selecting high-quality films and inks, which are fundamental to achieving vibrant and durable prints. By starting with solid foundational knowledge, new users can navigate the learning curve more efficiently.

Joining online communities and forums dedicated to DTF printing can also be beneficial. These platforms allow users to share experiences, troubleshoot issues, and learn from the successes and setbacks of others. Engaging with fellow enthusiasts fosters collaboration and can lead to discovering innovative tips and techniques that might hasten your proficiency in DTF printing. This supportive environment encourages continuous learning and improvement, allowing newcomers to excel in the custom apparel industry.

The Transformative Impact of DTF Printing on Creative Businesses

The advent of DTF printing technology is transforming creative businesses by providing them with unparalleled opportunities for customization and innovation. Clients seeking unique designs can now choose from a wider range of colors and materials, making the creative process more dynamic than ever. Businesses that utilize DTF transfers can respond quickly to design trends and customer requests, enabling them to stay ahead in a competitive marketplace.

Additionally, the cost-effectiveness of DTF printing allows creatives to expand their offerings without incurring significant financial risks. With the ability to produce high-quality, custom designs in short runs, artists and entrepreneurs can showcase their creativity without committing to large production runs. This flexibility not only inspires creative experimentation but also aligns perfectly with consumer trends towards individuality and personalized apparel.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique that involves printing designs onto a special film, which can then be heat-pressed onto various fabrics. This process allows for vibrant colors and intricate designs, making it perfect for custom apparel production. DTF technology is known for its versatility across materials like cotton and polyester.

What are the benefits of using DTF printing for custom apparel?

The benefits of DTF printing for custom apparel include vibrant color reproduction, durability of prints, and cost-effectiveness. DTF transfers are resistant to fading and washing, making them ideal for garments meant for frequent use. Additionally, they reduce setup costs for small batch jobs compared to traditional screen printing methods.

How does DTF printing differ from traditional screen printing?

DTF printing differs from traditional screen printing in several ways: DTF allows more versatility with different fabric types and produces more detailed prints. While screen printing requires a separate screen for each color, DTF transfers can print multiple colors at once onto a single film, streamlining the process and reducing costs for custom apparel.

What are some advantages of DTF transfers for businesses?

DTF transfers offer several advantages for businesses, such as higher production speed, the ability to handle custom orders efficiently, and reduced material waste. The technology also enables high-quality designs to be produced on-demand, catering to the growing trend of customized apparel in the market.

Are there environmental benefits associated with DTF printing?

Yes, there are environmental benefits associated with DTF printing. Many manufacturers are adopting eco-friendly inks and practices in the DTF printing process. This shift towards sustainability appeals to environmentally conscious consumers and can enhance a business’s competitive advantage in the custom apparel market.

What resources are available for beginners looking to learn DTF printing?

Beginners interested in DTF printing can find a variety of resources, including comprehensive guides that detail equipment setup, printing techniques, and heat-pressing methods. Community forums and social media groups are also excellent platforms for sharing tips and gaining insights from experienced users in the DTF printing community.

| Key Points | Description |

|---|---|

| Introduction | DTF transfers are transforming the custom apparel manufacturing landscape with enhanced design quality and streamlined production. |

| Understanding DTF Transfers | Involves printing designs on a special film to transfer onto fabrics, suitable for various materials including cotton and polyester. |

| Advantages | Vibrant prints, durability, cost-effectiveness make DTF an attractive option for businesses, especially in custom orders. |

| Latest Equipment | New printers and adhesive powders enhance the DTF process, offering compact and user-friendly options for businesses. |

| Market Trends | Growing demand for quick on-demand printing and eco-friendly practices is shaping the future of the DTF market. |

| Getting Started | Resources and community forums are available to learn DTF printing techniques and improve skills. |

Summary

DTF Transfers represent a breakthrough in custom apparel printing, offering businesses vibrant and durable designs with remarkable cost-efficiency. This technology is rapidly reshaping the fabric printing industry by meeting the needs of a market that thrives on quick turnarounds and personalization. As the demand for sustainable practices grows, DTF printing’s adaptability ensures its role as a key solution for modern custom apparel manufacturing. By leveraging the unique capabilities of DTF transfers, businesses can not only improve their production processes but also enhance customer satisfaction with high-quality outputs. Investing in this innovative technology could be the game-changer for those looking to thrive in the competitive apparel landscape.