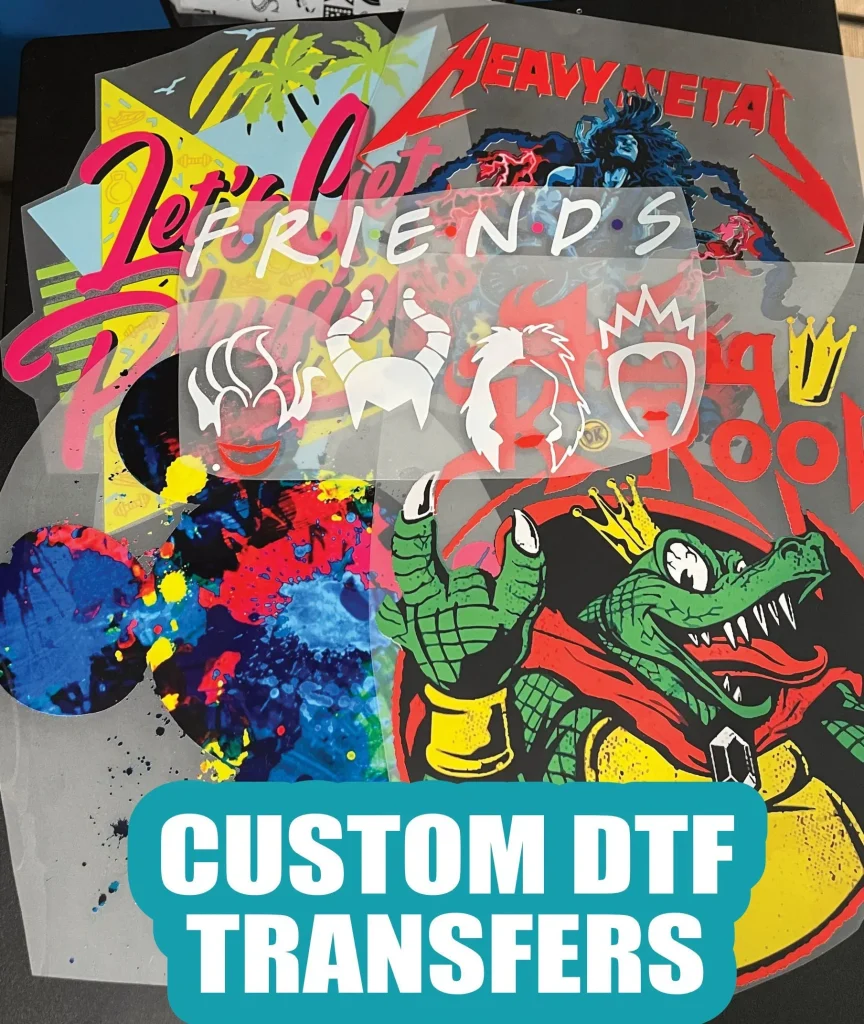

DTF transfers, or Direct to Film transfers, are transforming the way we approach custom apparel and textile printing. For beginners, this innovative method might seem intimidating at first glance, but fear not! With just a few key steps, you’ll learn how to use DTF transfers to craft stunning designs that adhere effortlessly to a variety of fabrics, from cotton to polyester. This beginner DTF guide is designed to walk you through everything you need to know, from the essential DTF printing advantages to detailed DTF transfer instructions. Whether you’re looking to create personalized gifts or launch a unique apparel line, mastering DTF transfers will elevate your printing skills to new heights.

When we talk about DTF printing, we refer to a cutting-edge technique that has gained popularity among DIY enthusiasts and professional printers alike. This method, often called Direct to Film technology, allows artists and creators to print intricate designs directly onto a special film before transferring them onto fabric. If you’re eager to explore how to use DTF transfers, including understanding their benefits and step-by-step instructions, you’re in for an exciting journey. With the right guidance and materials, even beginners can produce high-quality textile prints that boast vibrant colors and impressive durability. Join us as we delve into the essentials of DTF transfers and unlock the potential of your creative projects.

Understanding the Basics of DTF Printing

Direct to Film (DTF) printing is a modern technique that allows for high-quality and durable designs on various fabric types. As a beginner, grasping the basic functionalities of DTF transfers is crucial. This method involves printing your design onto a special film coated with a polymer, which can then be transferred onto fabrics using heat and pressure. Unlike traditional printing methods, DTF printing offers more vivid colors and the flexibility to print on multiple fabric types, including cotton, polyester, and blends, broadening your options for custom apparel.

By understanding the basics of DTF transfers, beginners can appreciate the advantages that this technology brings to the table. The process ensures that your designs are not only appealing but also resilient against wear and washing. Additionally, DTF printing is a cost-effective solution for small runs and personalized items, making it a perfect choice for artists and entrepreneurs alike. With thorough knowledge of the basic principles, you can embark on your journey in the custom printing world with confidence.

Gather the Right Materials for DTF Transfers

The first step in starting with DTF transfers is to collect all the essential materials. You will need a specialized DTF printer or a compatible inkjet printer that can handle the required inks. In addition, high-quality DTF transfer film is necessary to ensure that your designs adhere properly to the fabric. Another crucial component is the DTF powder adhesive, which helps bind the ink to the film and fabric during the transfer process. A reliable heat press machine is also indispensable to apply the necessary heat and pressure for successful transfers.

Moreover, using the right design software, like Adobe Photoshop or CorelDRAW, is key to creating stunning artworks. This software will allow you to design and customize your prints effortlessly. It’s advisable to invest in high-quality materials to achieve optimal results, as subpar products can lead to lower-quality prints, which can be disappointing in the end. Having all the materials at hand before beginning the DTF transfer process enhances efficiency and leads to better final outcomes.

Step-by-Step Guide to Using DTF Transfers

Now that you have gathered all the necessary materials, it’s time to delve into step-by-step instructions on how to use DTF transfers effectively. Start by preparing your design in the design software. This includes mirroring the design, ensuring that it’s printed in reverse on the transfer film. Choosing the right colors that will yield vibrant outputs on fabric is essential for a professional look. Once your design is ready, proceed to print it on the DTF transfer film with the appropriate printer settings.

After successfully printing your design, apply the DTF powder adhesive evenly over the wet ink to activate the bonding process. Then, cure the transfer by placing it in a heat press at the recommended temperature to solidify the adhesive. This crucial step ensures that your design adheres well to the fabric during the transfer. Following these instructions accurately will guarantee high-quality output and minimize potential mishaps, making the overall process smooth and enjoyable.

Preparing Your Fabric for DTF Transfers

Preparing your fabric properly before applying DTF transfers is critical to achieving the best results. Begin by pre-washing and drying your fabric to remove any residues such as sizing or chemicals that could interfere with adhesion. This step ensures that your design adheres correctly to the fabric and enhances its longevity. Choosing the right fabric is equally important, as DTF transfers work exceptionally well on cotton, polyester, and blends due to their ability to absorb the ink and adhesive effectively.

Once your fabric is prepared, ensure it is wrinkle-free before placing the DTF transfer on it. Use a lint roller to remove any particles that could mar the appearance of the final print. A clean, smooth surface contributes to a crisp transfer, enhancing the overall look of your finished product. By giving attention to these preparatory steps, you set the stage for a successful transfer that stands out and retains its quality wash after wash.

DTF Transfer Techniques for Professional Results

Mastering various techniques associated with DTF transfers can significantly elevate your printing game. One popular method is adjusting the temperature and pressure settings on your heat press to ensure optimal adhesion. Conducting test transfers on fabric scraps can help you fine-tune these settings before proceeding with your final designs. Experimenting with different heat times and temperatures will provide insight into how your specific materials respond, leading to perfectly printed apparel.

Another valuable technique involves layering designs for more complex visuals. Beginners can create unique looks by printing multiple transfers on top of each other, though attention must be paid to curing times and adhesive applications. This technique allows for creative freedom and intricate designs that are visually appealing and trendy. Most importantly, maintaining quality throughout the process is essential – always prioritize high-resolution artwork and reliable materials to achieve professional results.

Conclusion: Start Your Journey with DTF Transfers Today

In conclusion, DTF transfers are an accessible and effective printing method for those venturing into custom fabric designs. Following the provided instructions will not only boost confidence but also enhance your skills in creating eye-catching apparel. As you embark on your DTF journey, remember that practice makes perfect, and the more you experiment with designs, the better the outcomes you’ll achieve in your projects. Whether you’re making items for personal use or launching a small business, DTF printing can ignite your creativity.

Furthermore, don’t hesitate to explore forums and communities dedicated to textile printing and DIY crafts. Engaging with others who share your passion can provide invaluable support and insights into mastering DTF printing techniques. Stay updated on trends, tips, and best practices to continuously improve your craft. Begin your exciting journey with DTF transfers today, and unleash your artistic potential!

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a specially coated film that is then applied to fabric using heat. The process combines printing with a unique adhesive powder, creating vibrant and durable designs that adhere well to various materials.

What materials do I need for DTF printing?

To successfully create DTF transfers, you’ll need a DTF printer, DTF transfer film, DTF powder adhesive, a heat press machine, and design software like Adobe Photoshop or CorelDRAW. These materials are essential for ensuring high-quality prints.

How do I use DTF transfers effectively?

Using DTF transfers involves several steps: create and mirror your design in design software, print it onto DTF transfer film, apply adhesive powder, cure the transfer with heat, and then use a heat press to transfer the design onto your chosen fabric.

What are the advantages of DTF printing compared to other methods?

DTF printing offers several advantages including versatility across different fabrics, high durability against cracking or fading, vivid color representation, and the ability to easily create custom designs for small runs or personalized apparel.

Are there specific instructions I should follow for DTF transfer application?

Yes, for successful DTF transfer application, ensure that your design is mirrored before printing, use the correct heat and pressure settings during transfer, and allow the printed film to cool slightly before peeling to achieve the best adhesion and finish.

Can beginners easily learn how to print with DTF transfers?

Absolutely! A beginner DTF guide can help you navigate the process step by step. With the right materials and attention to detail in each step, anyone can learn DTF printing and create professional-quality designs.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Printing designs on coated film, combining with adhesive, and bonding to fabric using heat. |

| Advantages of DTF Transfers | Versatile, durable, vivid colors, and customizable for small runs. |

| Materials Needed | Specialized DTF printer, transfer film, powder adhesive, heat press, design software. |

| Step 1: Gather Your Materials | Collect necessary tools before starting your DTF project. |

| Step 2: Create Your Design | Design art in software, mirror it, and select vibrant colors. |

| Step 3: Printing the Design | Load film into printer, set appropriate settings, and print the design. |

| Step 4: Apply Powder Adhesive | Add adhesive over wet ink, tap off excess for smooth application. |

| Step 5: Cure the Transfer | Heat press at 160°C for 30 seconds to bond adhesive to ink. |

| Step 6: Heat Transfer Process | Apply heat and pressure to transfer design onto fabric for 10-15 seconds. |

| Step 7: Peel the Film | Peel away film after cooling; a warm peel is recommended. |

| Step 8: Final Press (Optional) | Final pressing may be done to enhance durability of transfer. |

Summary

DTF Transfers are transforming custom printing, providing an accessible and efficient method for creating stunning designs. For beginners, understanding DTF transfers is essential for embarking on a journey in textile printing. This technique combines creativity with the ability to produce durable and vibrant prints on various fabrics, making it ideal for personal and professional use. By following the step-by-step guide and utilizing high-quality materials, anyone can master DTF transfers and unleash endless possibilities in custom apparel design.