Welcome to the exciting world of the **DTF Gangsheet Builder**! This innovative tool is revolutionizing how designers approach the Direct-to-Film (DTF) printing process, offering an efficient way to create stunning apparel designs. In this guide, we will provide you with essential DTF printing tips that can enhance your gangsheet design, ensuring that your artwork appears vibrant and accurate. Mastering the DTF Gangsheet Builder not only optimizes your color management in printing but also streamlines your workflow, making it easier than ever to transfer your creative visions onto various fabrics. Whether you’re a novice or a seasoned pro, understanding this builder will elevate your design process and help you achieve flawless results every time.

Dive into the world of Direct-to-Film (DTF) printing with our comprehensive overview of the **DTF Gangsheet Creator**. As a vital application for designers, this software enables efficient gangsheet generation, maximizing fabric and film usage in the print production process. By harnessing advanced design software, you can focus on crafting artworks that benefit from optimized color management and effective printing strategies. From creating vibrant apparel prints to learning about the nuances of the DTF printing technique, integrating these tools into your workflow will enhance both your creative output and overall printing efficiency. Whether you’re preparing for personal projects or professional endeavors, embracing the capabilities of the DTF Gangsheet Creator will set you on the path to success.

Understanding DTF Printing and Its Benefits

DTF printing, or Direct-to-Film printing, is a revolutionary technique thatoffers unparalleled versatility for customizing apparel. This process enables designers to transfer intricate and vibrant designs onto various textiles with remarkable ease. Unlike traditional methods that often require separate setups for each garment, DTF printing allows for multiple designs to be printed on a single film, reducing waste and saving time during the print process. It’s especially beneficial for small runs and unique projects, making it a go-to choice for custom apparel businesses.

The efficiency of the DTF printing process is complemented by its ability to produce designs that are both detailed and durable. The application of special inks and adhesive powders during the printing process ensures that the designs adhere securely to the fabric, resulting in high-quality prints that withstand wear and tear. For designers looking to fulfill client orders quickly without compromising quality, mastering DTF printing can lead to significant competitive advantages in the crowded market of apparel customization.

Essential Graphic Design Software for DTF Printing

When entering the world of DTF printing, familiarizing yourself with top graphic design software is crucial for crafting exceptional designs. Software like Adobe Illustrator and CorelDRAW are widely used in the industry because they provide the tools needed to create and manipulate vector graphics, which are essential for achieving sharp and clean prints. Understanding these tools not only helps with design aesthetics but also plays a vital role in preparing files that are compatible with the DTF printing process.

Moreover, mastering features such as layer management and color profiles in design software can enhance color management in printing. For instance, using CMYK color modes ensures that the colors you see on your screen closely match the final product. Investing time in learning these design platforms will pay off in the long run, as it increases your capacity to create intricate gangsheet designs that stand out and meet client expectations.

Maximizing Efficiency with DTF Gangsheet Builder Tools

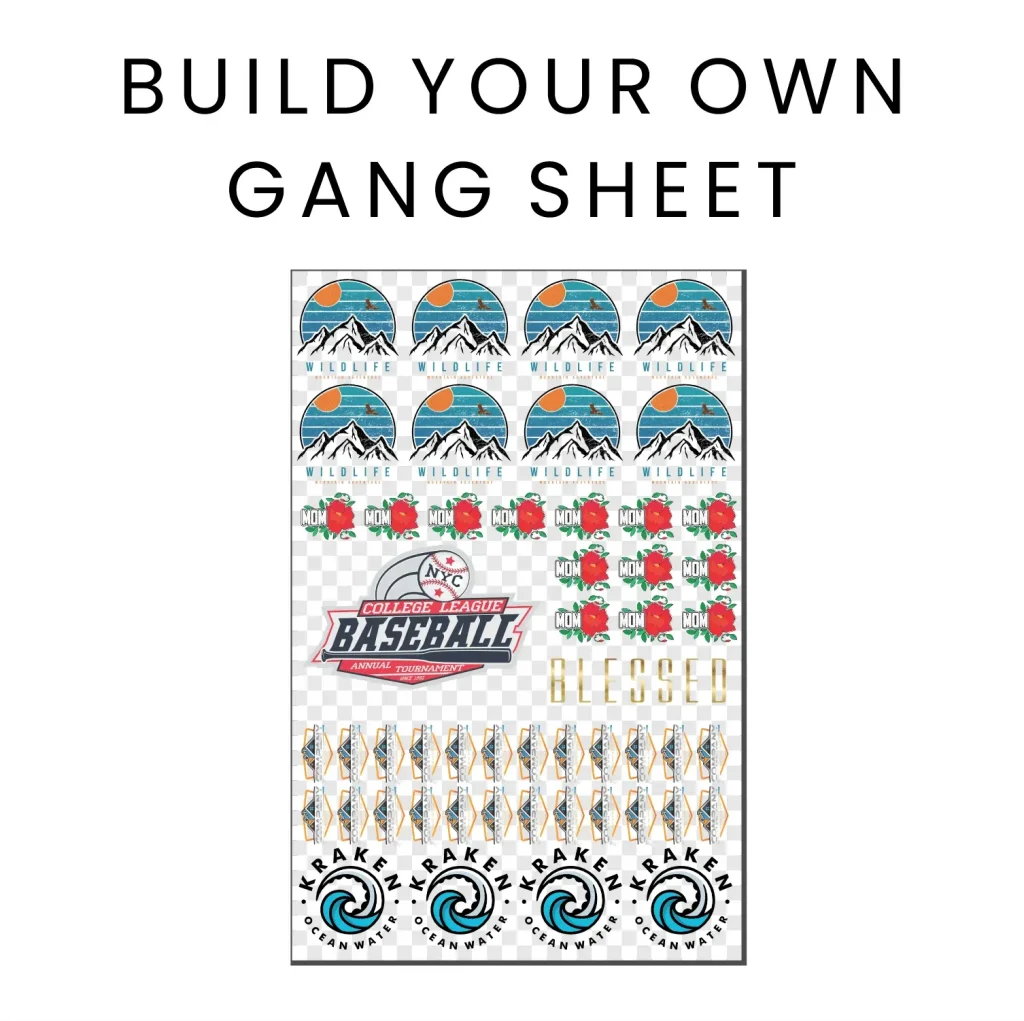

Utilizing DTF gangsheet builder tools can significantly streamline your printing process. These online platforms allow you to upload and arrange multiple designs into a single, cohesive layout, optimizing the use of your film. With intuitive features that enable resizing, rotating, and aligning images, you’ll be able to achieve a professional finish without the hassle of manually adjusting each item. This efficiency not only saves time but also minimizes film waste, aligning with best practices in sustainable printing.

To get the most out of a DTF gangsheet builder, take the time to familiarize yourself with its unique features, such as maintaining resolution during scaling and ensuring proper alignment across designs. Understanding these capabilities will help you avoid common pitfalls and enhance the quality of your prints. Engaging with the software’s tutorials or community forums can provide additional tips and tricks that can elevate your design game.

The Importance of Color Management in DTF Printing

Color management is a crucial aspect of DTF printing that can significantly affect the quality of your final product. By utilizing specific color profiles, you can ensure that the colors appearing on screen closely align with the actual prints. Conducting regular test prints and creating color swatches will help fine-tune your color settings, allowing for better precision in your designs. This process not only enhances satisfaction among clients but also builds your reliability as a designer.

Additionally, understanding the interplay between different inks and fabrics is pivotal in achieving the desired hue and vibrancy. Each fabric type may react differently with the DTF inks, which makes investing time in color experiments a worthwhile effort. Striving for consistency through effective color management will ensure that your designs stand out with the vividness and clarity that clients expect from high-quality custom apparel.

Optimizing Print Settings for Flawless Results

Optimizing your print settings is one of the most vital steps in achieving flawless DTF prints. This entails adjusting parameters such as DPI (dots per inch) and print speed to suit the specific characteristics of the DTF films you are utilizing. Higher DPI settings typically yield better detail, while the print speed can influence the depth of ink saturation. Taking the time to calibrate these settings can make a significant difference in the quality of the final output, ensuring that designs are sharp and vibrant.

Furthermore, being acquainted with the required ICC profiles for your printer and ink will help you maintain color accuracy throughout the printing process. Each profile is designed to match the specific capabilities of your equipment, resulting in more predictable outcomes. By properly managing your print settings, you not only enhance the overall quality of your designs but also improve your efficiency and reduce unnecessary costs associated with reprints.

Pre-Treatment and Post-Processing Techniques for DTF

Pre-treatment and post-processing are essential components of the DTF printing process that can greatly affect the longevity and durability of your designs. During pre-treatment, applying a specific adhesive powder to the film enhances its ability to bond with fabrics during the transfer process. Neglecting this vital step can lead to peeling or fading, undermining the trust clients place in your products.

Post-processing, which involves curing or heat setting the printed film, is equally important for ensuring the design’s solidity. This step not only seals the ink but also guarantees that the colors stay vibrant even after multiple washes. Implementing a consistent regimen of pre-treatment and post-processing will ultimately result in high-quality prints, positioning you as a reliable choice for custom apparel among your customers.

Frequently Asked Questions

What is the DTF printing process and how does the DTF Gangsheet Builder fit into it?

The DTF printing process, or Direct-to-Film printing, involves transferring designs onto fabrics using a film as a medium. The DTF Gangsheet Builder allows users to design and organize multiple images on one film sheet, maximizing efficiency and minimizing waste during the printing process.

How can I optimize my designs for the DTF Gangsheet Builder?

To optimize your designs for the DTF Gangsheet Builder, ensure you use high-resolution images in compatible formats like PNG or TIFF, maintain transparent backgrounds, and arrange your designs thoughtfully on the gangsheet to utilize space effectively.

What graphic design software is best for creating files for the DTF Gangsheet Builder?

Popular graphic design software for preparing files for the DTF Gangsheet Builder includes Adobe Illustrator and CorelDRAW. These programs support vector graphics and advanced color management, which are crucial for producing stunning designs suited for DTF printing.

What are some essential color management tips for DTF printing?

For effective color management in DTF printing, use specific ICC profiles for your printer, perform color tests and swatch creation, and adjust your monitor settings to reflect print colors accurately. This ensures consistency between your digital designs and the final printed output.

How does pre-treatment affect designs created with the DTF Gangsheet Builder?

Pre-treatment is vital for designs printed using the DTF Gangsheet Builder as it enhances adhesion between the film and fabric during the transfer process, leading to more durable and vibrant prints that last longer.

Are there any common issues to watch for when using the DTF Gangsheet Builder?

Common issues when using the DTF Gangsheet Builder include color discrepancies, misalignment of designs, and incorrect print settings. Keeping a troubleshooting guide and maintaining communication with your film supplier can help address these challenges effectively.

| Key Aspect | Details |

|---|---|

| What is DTF Printing? | A printing technique transferring designs onto fabrics using a gangsheet to maximize efficiency. |

| Familiarize with Graphic Design Software | Proficiency in tools like Adobe Illustrator and CorelDRAW is crucial. Save designs in PNG or TIFF formats with transparent backgrounds. |

| Utilize DTF Gangsheet Builder Tools | Online builders help upload, arrange, and resize designs on a single sheet, ensuring resolution and alignment are maintained. |

| Master Color Management | Use specific color profiles for DTF to ensure accuracy between screen and print colors with tests and swatches. |

| Optimize Print Settings | Adjust print settings including ICC profiles and DPI for better detail and ink saturation according to DTF films specifications. |

| Pre-Treatment and Post-Processing | Enhance adhesion and design durability by properly pre-treating and post-processing the film. |

| Batch Processing is Key | Group smaller designs on one sheet to maximize film usage and save time. |

| Stay Updated on Industry Trends | Engage with community forums and blogs to keep informed about new techniques and tools. |

| Troubleshoot Common Issues | Keep a log of issues and solutions and communicate with tech support for effective problem resolution. |

Summary

The DTF Gangsheet Builder is an essential tool for anyone looking to excel in Direct-to-Film printing. Mastering the nuances of this builder, from understanding graphic design software to optimizing print settings, equips designers with the skills needed to create impeccable prints. Adopting best practices such as effective color management, batch processing, and thorough troubleshooting will greatly enhance your efficiency and output quality. By staying informed with ongoing industry trends and innovations, you ensure your designs not only meet but exceed quality standards. Explore the full potential of the DTF Gangsheet Builder today, and unlock the ability to produce vibrant and lasting designs that stand out in the competitive realm of apparel customization.