In the dynamic landscape of custom apparel printing, DTF gangsheets printing is emerging as a game changer, offering a unique blend of quality and efficiency. This innovative technique involves using high-resolution transfer films to create eye-catching designs that can be applied to a variety of fabrics. Unlike traditional printing methods like screen printing and direct-to-garment (DTG) printing, DTF gangsheets allow for multiple designs to be printed on a single sheet, streamlining production and reducing costs. With numerous benefits including vibrant colors and durability, DTF printing is quickly becoming the preferred choice for businesses looking to satisfy diverse customer needs. As we explore the advantages and applications of DTF gangsheets, we will compare them to established methods, providing insight into their growing popularity in the custom apparel market.

When it comes to innovative techniques in the apparel industry, many are turning to Direct-to-Film (DTF) printing as a leading option for textile design. This method, which involves printing on specialized films before transfers are applied to garments, is revolutionizing how custom apparel is produced compared to traditional techniques such as screen printing and direct-to-garment methods. The flexibility of DTF gangsheets allows manufacturers to handle multiple designs in a single run, significantly improving efficiency. In this discussion, we will not only highlight the benefits of using DTF printing but also shed light on its impact on the overall production process in the custom apparel sector. Join us in exploring how this modern printing solution is reshaping the market landscape.

Understanding DTF Gangsheets Printing

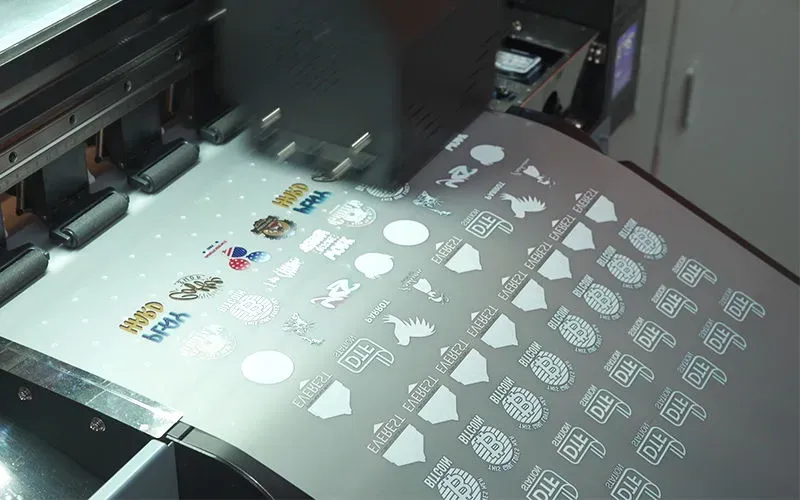

DTF gangsheets printing is revolutionizing the landscape of custom apparel manufacturing. By utilizing specialized films, this printing process allows designers to print multiple graphics on a single sheet, significantly aiding in dynamic printing options. This technique not only maximizes efficiency but also enhances creativity, as multiple designs can be combined and transferred onto garments with precision and vibrant color acuity. Businesses aiming to diversify their offerings will find DTF printing to be a versatile solution that meets varied consumer demands.

Unlike traditional printing methods like screen printing, DTF gangsheets enable intricate details and gradients to be captured seamlessly on fabrics. As the technology behind DTF printing continues to advance, its appeal becomes even stronger, particularly for small to medium runs that require flexibility and adaptability without compromising on quality. With an ever-growing competitive market in custom apparel printing, understanding the intricacies of DTF gangsheets is crucial for businesses looking to stay ahead.

Advantages Over Traditional Printing Methods

One of the most notable advantages of DTF gangsheets printing is operational efficiency. Compared to traditional printing methods, such as screen printing and direct-to-garment (DTG) printing, DTF significantly reduces production time. Because the sheets can accommodate multiple designs, businesses can fulfill diverse orders faster, translating to increased profitability. Additionally, DTF printing eliminates the need for extensive setup times and costs that traditional methods often impose, especially when handling unique or multi-color designs.

Moreover, DTF printing maintains a high-quality standard that often surpasses traditional methods. While screen printing can struggle with intricate designs due to the setup of individual screens, DTF technology ensures that even the most complex imagery is rendered with clarity and vibrancy. This level of detail is particularly appealing to fashion brands seeking to differentiate themselves through unique custom designs, ultimately making DTF gangsheets a more versatile and strategic choice.

Cost Efficiency of DTF Gangsheets Compared to Traditional Methods

Cost efficiency is a paramount concern for any custom apparel printing business. DTF gangsheets stand out for their ability to reduce costs significantly, particularly for small to medium-sized orders. Because various designs can be printed on a single sheet, businesses experience a marked reduction in material waste and printing setup expenses. This is especially beneficial for those catering to niche markets or specific customer requests, allowing for tailored solutions that do not compromise financial viability.

In contrast, traditional printing methods, while cost-effective at scale, often incur high upfront costs due to setup processes. For screen printing, each new design necessitates creating screens, which can be time-consuming and expensive. As such, businesses with varying orders might find that the onset costs outweigh the benefits of traditional methods. DTF printing provides a financially viable alternative by allowing rapid deployment of designs without the associated setup burdens.

Production Speed: DTF Printing Versus Traditional Methods

In the fast-paced world of custom apparel, production speed can make or break a business. DTF gangsheets printing is designed for efficiency, boasting rapid turnaround times that cater to urgent customer demands. Once the designs are printed onto the film, applications onto garments can be executed swiftly, making it an ideal choice for businesses that prioritize quick delivery periods. This capability ensures that brands can respond readily to market trends or last-minute orders, thus cementing their reputation for reliability.

Conversely, traditional printing methods often involve more intricate preparation processes that can hinder production speed. Screen printing, while capable of producing large quantities efficiently, still requires considerable time for setup and design preparation. This bottleneck can lead to delays, especially in scenarios that require agility or rapid response to changes in consumer preferences. Thus, businesses that embrace DTF printing will find that enhanced production speed not only satisfies customer demands but also fosters a competitive edge.

Environmental Impact of DTF Gangsheets Printing

Environmental considerations are increasingly becoming a focal point in the printing industry, especially as consumers demand more sustainable practices. DTF gangsheets printing stands out not only for its efficiency but also for its reduced environmental footprint. The printing process utilizes fewer inks and solvents, which translates to less waste and lower emissions. This environmentally friendly approach positions DTF printing favorably against traditional methods, many of which have significant resource-intensive processes.

On the other hand, traditional printing methods such as screen printing often involve hazardous substances and create excess waste from screens and materials. As regulations around environmental impacts tighten, printing businesses must adapt by exploring greener alternatives. Implementing DTF printing can help companies align their operations with growing sustainability trends and cater to environmentally conscious consumers, ultimately enhancing brand loyalty.

Future of Custom Apparel Printing: The Rise of DTF Technology

The landscape of custom apparel printing is witnessing a significant shift, with DTF technology poised to dominate in the coming years. As businesses increasingly recognize the numerous advantages offered by DTF gangsheets, including cost savings, production speed, and exceptional print quality, the adoption of this technology is projected to rise. This transition reflects a broader trend within the industry towards more versatile, on-demand solutions that cater to the dynamic needs of consumers.

Furthermore, the ongoing advancements in DTF technology promise even greater enhancements in print resolution and efficiency. As manufacturers innovate, the capabilities of DTF printing will expand, potentially allowing for even more intricate designs and better integration with various fabrics. This means that custom apparel manufacturers who invest now in DTF gangsheets printing will likely find themselves at the forefront of the market, ready to meet future consumer demands with agility and precision.

Frequently Asked Questions

What are the advantages of DTF gangsheets printing over traditional printing methods?

DTF gangsheets printing offers several advantages over traditional methods like screen printing and direct-to-garment printing. Notably, it provides exceptional print quality with vibrant colors, accommodates multiple designs on a single sheet, reduces material costs for smaller orders, and allows for faster production times. These factors make DTF gangsheets a preferred choice for businesses focused on efficiency and high-quality custom apparel.

How does DTF printing compare to screen printing in terms of design flexibility?

DTF printing excels in design flexibility compared to screen printing. While screen printing requires creating separate screens for each color, DTF gangsheets can handle intricate and detailed designs with high precision and vibrant output. This allows for a wider range of design options, making DTF gangsheets ideal for complex, multi-color artworks commonly found in custom apparel.

What is the cost-effectiveness of DTF gangsheets printing for small order sizes?

DTF gangsheets printing is particularly cost-effective for small orders as it allows for the printing of multiple designs on one sheet, reducing setup time and material costs. This feature is especially beneficial for custom apparel businesses targeting local markets or fulfilling personalized orders without incurring high overhead costs often associated with traditional printing methods.

How does the production speed of DTF printing impact turnaround times for custom apparel?

The production speed of DTF gangsheets printing significantly enhances turnaround times for custom apparel orders. Once the film is printed, transfers can be applied quickly to garments, streamlining the production process. This efficiency is crucial for businesses that require rapid fulfillment of urgent orders, which is a common limitation with traditional printing methods.

Are the prints from DTF gangsheets durable compared to those from traditional printing methods?

Yes, prints from DTF gangsheets are known for their durability compared to those from traditional methods. DTF printing creates high-resolution images that do not easily fade or peel, ensuring long-lasting quality in custom apparel. This durability makes DTF gangsheets a reliable option for businesses looking to deliver quality products to their customers.

What environmental considerations are there when using DTF gangsheets printing?

DTF gangsheets printing is often seen as a more environmentally friendly option compared to traditional printing methods. This process typically uses less water and fewer chemicals than screen printing, resulting in a lower environmental impact. Additionally, the efficiency in production and material usage contributes to a more sustainable approach in the custom apparel printing industry.

| Feature | DTF Gangsheets Printing | Traditional Printing |

|---|---|---|

| Print Quality | Exceptional quality with high resolution and vibrant colors. Durable prints that do not fade easily. | Good quality, but constraints on design complexity. Longer production times with higher costs for intricate designs. |

| Cost Efficiency | Cost-effective for smaller orders due to multiple designs on one sheet, reducing material costs and setup time. | Benefits larger orders due to economies of scale, but setup costs can be prohibitively expensive for small runs. |

| Production Speed | Faster turnaround times, especially for short runs, with quick transfer application. | Initial preparation time for setups can slow down production speed, especially for intricate designs. |

Summary

DTF gangsheets printing represents a revolutionary approach in the custom apparel industry, redefining efficiency and quality. By leveraging advanced Direct-to-Film technology, businesses can deliver vibrant, detailed designs quickly and cost-effectively, especially for smaller runs. This method’s ability to consolidate multiple designs onto a single sheet not only minimizes material waste but also accelerates production times, making it ideal for responding to diverse customer demands. As companies continue to adapt to market needs and consumer preferences, DTF gangsheets printing stands out as a superior choice, combining the best aspects of modern printing technology.