In the dynamic landscape of textile printing, DTF transfers have quickly established themselves as a revolutionary method for crafting custom apparel. Direct to Film printing merges the advantages of traditional techniques like dye sublimation and heat transfer, enabling artisans to achieve vibrant, high-definition prints on a variety of fabrics. The DTF printing technique is not only efficient but also adapts seamlessly to both light and dark materials, making it a versatile choice for designers. As the DTF market growth continues to surge, driven by an increasing consumer demand for personalized and eco-friendly printing options, it’s clear that this innovative approach is shaping the future of custom design in the fashion industry. By embracing DTF transfers, businesses can tap into a powerful tool that enhances creativity while promoting sustainability in their production processes.

Exploring the world of Direct to Film (DTF) printing unveils a fascinating avenue for those interested in personalized fabric designs. Often referred to as film-based transfer printing, this method is transforming how businesses and creators produce custom apparel and promotional merchandise. The technique’s adaptability allows for intricate graphics to be transferred onto an array of textiles, ensuring that designers can meet varied customer needs. As sustainability becomes paramount in production practices, the eco-friendly nature of DTF printing emerges as a compelling alternative to traditional methods. With the DTF approach gaining traction, it’s more crucial than ever to understand its implications for the future of the apparel and textile industries.

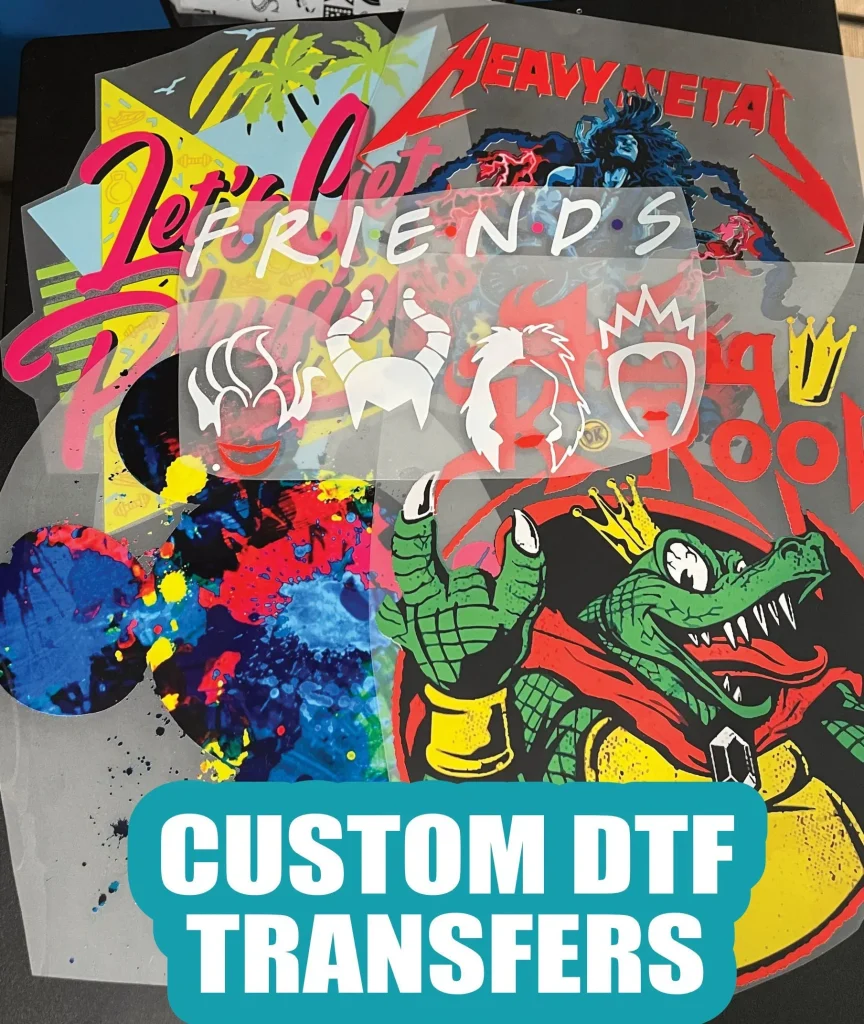

The Mechanics of DTF Transfers

Understanding the mechanics of Direct to Film (DTF) transfers is essential for anyone interested in modern printing techniques. This innovative process starts with high-quality, specialized inks that are printed onto a thin film. The key to successful DTF printing lies in the combination of these inks with an adhesive powder that bonds with the print. After applying heat, the design adheres flawlessly to the fabric, allowing the printer to achieve complex designs with incredible detail. Unlike traditional methods that often struggle with color vibrancy on dark fabrics, DTF provides a consistent output across various materials.

The versatility of DTF transfers enhances their application across multiple sectors, from custom apparel to promotional items. This technique is not only effective for t-shirts and hoodies, but it also works seamlessly on intricate designs for sportswear and activewear. Because it is capable of handling complex graphics without compromising on quality, DTF printing is becoming increasingly favored for high-demand applications and detailed projects.

Unpacking the DTF Printing Technique

DTF printing encompasses a unique method that blends innovative technology with user-friendly processes. The DTF printing technique stands out because it allows for direct application of vibrant colors onto different fabric types. By leveraging the heat transfer process, the ink is embedded directly into the material, providing an end result that not only looks outstanding but also wears well over time. This makes DTF an attractive option for businesses seeking to produce high-quality custom apparel with ease.

Moreover, the DTF technique opens the door to various creative possibilities, as it does not limit users to specific design types or color palettes. Fashion designers and custom apparel businesses can explore their artistic potential freely, producing detailed images, gradients, and even photographic prints on textiles. The flexibility afforded by DTF printing can dramatically impact branding efforts, making unique apparel more accessible to diverse creators.

Environmental Impact of DTF Printing

As sustainability continues to be a pressing concern in manufacturing, DTF printing emerges as a leading eco-friendly alternative. The process utilizes significantly less water compared to traditional dyeing methods and minimizes the use of harsh chemicals, making it a more environmentally conscious printing solution. This aspect resonates well with today’s consumers who increasingly prioritize eco-friendly products, leading businesses to consider DTF as a viable option for sustainable manufacturing practices.

Furthermore, as more companies adopt DTF printing, the impact on the textile industry landscape can be quite profound. By prioritizing eco-friendly processes and materials, businesses can align themselves with consumer values, boosting their brand image and customer loyalty. As the DTF market continues to grow, the emphasis on sustainable practices only amplifies the appeal of this innovative printing technique.

The Rise of the DTF Market

Recent trends indicate a substantial rise in the DTF market, particularly following the global shift towards personalization and custom products. With the capabilities of DTF printing, businesses can quickly produce unique items tailored to consumers’ preferences, driving a significant increase in demand for custom apparel. Market growth statistics reflect this shift, highlighting a promising future for direct to film technology as it disrupts traditional printing methods.

The growth of the DTF market also signals an opportunity for entrepreneurs and small businesses to enter the custom printing landscape without the burden of high costs associated with traditional printing. With affordable and compact DTF printing machines entering the market, it becomes feasible for startups to create tailored products that meet customer demands efficiently. This democratization of technology fuels innovation and competition within the textile industry.

Challenges in DTF Printing

Despite the advantages of DTF printing, there are notable challenges that users must navigate to achieve optimal results. Proper adhesion and curing of the prints are crucial for durability and quality. Users may encounter initial struggles related to the intricate balance of temperature and timing during the transfer process. However, the growing community of DTF printers encourages sharing solutions and techniques, aiding users in overcoming these hurdles.

Additionally, as the technology evolves, so does the necessity for ongoing research to optimize and tackle these challenges effectively. Innovations in ink formulations and printing processes are progressively addressing issues surrounding print longevity and wash resistance. By actively engaging with the community and staying updated with advancements, DTF users can mitigate obstacles and benefit from superior print quality.

Future Trends in DTF Technology

Looking towards the future, DTF technology is likely to undergo remarkable advancements that will enhance print quality and application versatility. As designers and businesses explore new avenues for customization, the capabilities of DTF printing will expand to meet growing consumer demands. The incorporation of new materials and eco-friendly inks may become standard practice in DTF printing, aligning with the trend towards sustainability and innovation in the textile industry.

Moreover, the continuous improvement in DTF printing equipment will pave the way for higher productivity and efficiency for businesses ranging from small startups to larger enterprises. Enhanced user interfaces and automated features in DTF printers could facilitate a more straightforward production process, making high-quality custom apparel accessible to a broader audience. The future of DTF is bright, suggesting an ongoing evolution that aligns with consumer values and market trends.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs directly onto a specialized film, which is then heat-pressed onto fabrics. This technique allows for vibrant, detailed prints on a variety of materials, making it ideal for custom apparel.

What are the benefits of using the DTF printing technique for custom apparel?

The DTF printing technique offers numerous benefits for custom apparel, including vibrant colors, detailed graphics, and compatibility with both light and dark fabrics. It simplifies the printing process with a single solution, requiring less setup compared to traditional methods.

How does the DTF market growth reflect trends in eco-friendly printing?

The DTF market has experienced significant growth as consumer preferences shift towards custom, eco-friendly products. DTF printing typically uses fewer resources and non-toxic inks, making it a sustainable choice in textile printing that appeals to environmentally conscious customers.

What kinds of custom apparel can be produced using DTF transfers?

DTF transfers can be used to produce a wide range of custom apparel including t-shirts, hoodies, hats, and more. Its versatility makes it suitable for both everyday wear and promotional merchandise.

What innovations have contributed to the popularity of DTF printing technology?

Recent innovations in DTF printing equipment, such as compact and user-friendly printers, have made this technology more accessible to small businesses and individuals. Improved ink formulations also enhance durability and wash resistance, boosting its appeal in the custom apparel market.

What challenges are associated with DTF transfers, and how are they being addressed?

Challenges with DTF transfers include ensuring proper adhesion and curing. Ongoing research and development are focused on optimizing inks and processes to improve performance, thereby helping to maintain DTF’s reputation for delivering high-quality print results.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers are a printing method where designs are printed onto a film, then heat-transferred to fabrics, providing high-quality prints on various materials. |

| Technique and Applications | Offers vibrant, detailed designs perfect for complex graphics, using specialized inks and adhesive powder for chemical adherence to fabric. |

| Market Growth | The DTF transfer market is growing rapidly due to the increased demand for personalized apparel post-pandemic. |

| Equipment Innovations | Recent developments in user-friendly, compact printing equipment have lowered costs and increased accessibility for small businesses. |

| Eco-Friendly Practices | DTF printing is more sustainable compared to traditional methods, using less water and fewer harmful chemicals, appealing to eco-conscious consumers. |

| Challenges and Considerations | Some users face challenges with adhesion and curing, prompting ongoing research to enhance print quality and resolve issues. |

| Practical Applications | Ideal for custom apparel, sportswear, and promotional merchandise, offering a wide range of customization options. |

Summary

DTF transfers revolutionize the textile printing industry by offering a high-quality, versatile solution for custom designs on various fabrics. This innovative printing technique combines the benefits of traditional methods while addressing the growing need for personalization in apparel. As businesses and consumers prioritize eco-friendliness and sustainability, DTF transfers not only meet these demands but also enhance the creative possibilities for designers. The advancement of DTF technology ensures that it will continue to be a key player in the future of custom printing, providing essential benefits to both creators and consumers.