DTF transfers have emerged as a groundbreaking technology in the custom printing industry, revolutionizing how businesses create and deliver personalized apparel. By combining the efficiency of digital printing with the versatility of traditional methods, DTF printing is enabling companies to produce intricate and vibrant designs quickly and affordably. This innovative approach to apparel printing eliminates many of the complexities associated with traditional techniques, making it accessible to both small businesses and large enterprises. As demand for custom products rises, DTF transfers are increasingly recognized for their ability to meet the needs of consumers looking for unique and personalized items. In this article, we’ll delve into the transformative impact of DTF technology on the world of custom printing, and why it’s critical for businesses to leverage these advancements for future success.

Also known as Direct-to-Film printing, this method has become synonymous with cutting-edge digital printing solutions tailored for custom apparel. DTF technology seamlessly bridges the gap between high-quality production and the immediacy needed in today’s fast-paced market. Its ability to cater to diverse customization requests positions it as a favored choice among both entrepreneurs and established brands alike. Whether referred to as garment printing or personalized design transfer, the principles behind DTF remain focused on delivering durable, vibrant results that satisfy the growing consumer appetite for distinctive merchandise.

Understanding the DTF Printing Process

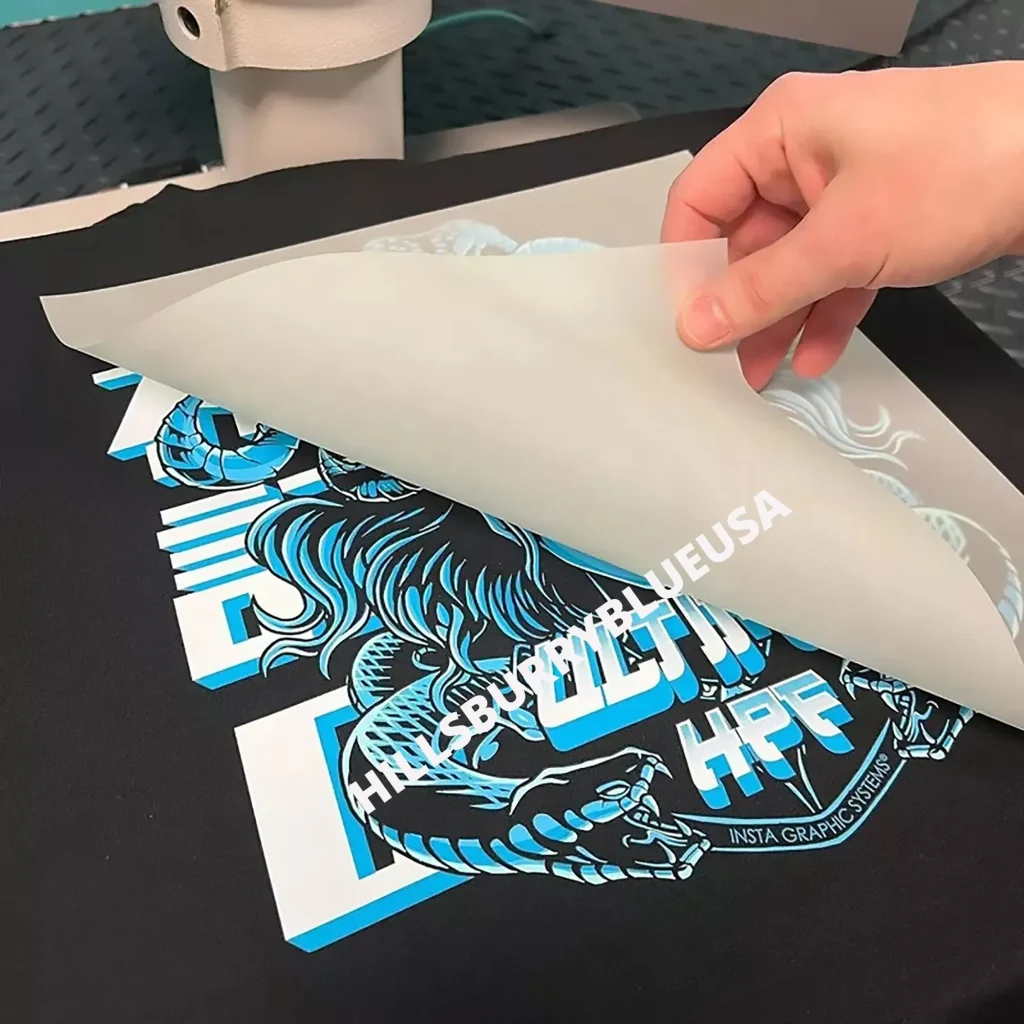

DTF printing, or Direct-to-Film printing, is a revolutionary technique that marries the precision of digital printing with the benefits of traditional methods. This innovative process begins with a specialized film coated in adhesive, onto which vibrant designs are printed using advanced digital printers. The printed film is then applied to the desired fabric under heat and pressure, allowing the design to adhere seamlessly. This method not only ensures high-quality prints but also broadens the palette of colors and designs that can be accurately replicated. Its simplicity and efficiency make DTF a preferred choice for both small businesses and large-scale apparel manufacturers.

Moreover, DTF printing caters to a wide array of fabrics, from cotton to polyester, enabling businesses to produce a diverse range of products, including t-shirts, hoodies, and bags. The versatility of DTF technology makes it an enticing option for various applications, from promotional merchandise to personalized apparel. As companies strive to meet the growing demand for unique and high-quality products, understanding and implementing DTF printing processes can significantly enhance their market competitiveness.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

DTF Transfers, or Direct-to-Film transfers, are a cutting-edge method in custom printing that involves printing designs onto a specialized film. Adhesive is applied to these prints, and heat is used to transfer them onto the desired material. This process allows for vibrant and detailed designs, ideal for apparel printing and personalized products, without the complexities of traditional printing methods.

Why are DTF Transfers becoming popular in the apparel printing industry?

DTF Transfers are gaining popularity in the apparel printing industry due to their ability to produce high-quality, durable prints with vibrant colors. This digital printing technology offers quick turnaround times and no minimum order requirements, making it accessible for both large and small businesses. These features meet the growing consumer demand for custom and personalized apparel.

How do DTF Transfers compare to traditional screen printing?

Unlike traditional screen printing, which requires extensive setup and large production runs, DTF Transfers streamline the printing process. They provide flexibility with on-demand printing, allowing businesses to create custom designs without the need for minimum orders. This efficiency, combined with superior print quality and durability, positions DTF transfers as a preferred choice for modern custom printing.

What advantages do DTF Transfers provide for small businesses in custom printing?

DTF Transfers empower small businesses by allowing them to compete effectively in the custom printing market. With no minimum order requirements and fast production times, small brands can offer personalized apparel without facing significant upfront costs. This accessibility encourages entrepreneurship and enables smaller companies to meet unique customer demands.

How do advancements in DTF printing technology influence the custom printing landscape?

Advancements in DTF printing technology are reshaping the custom printing landscape by enhancing quality, speed, and accessibility. These innovations encourage broader adoption of digital solutions, facilitate quick order fulfillment, and enable businesses to offer more personalized products. As a result, DTF transfers are paving the way for more dynamic and responsive custom printing environments.

What future trends can be anticipated for DTF Transfers in the custom printing industry?

Future trends for DTF Transfers in the custom printing industry include increased integration of automation and technology, further enhancements in print quality, and a growing focus on sustainability. As consumer preferences shift towards personalized products, DTF technology will likely continue to evolve, supporting businesses in meeting the demand for unique, high-quality apparel printing.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | DTF transfers combine digital printing and traditional methods to create vibrant designs on various materials, with a simpler setup compared to traditional screen printing. |

| The Rise of DTF Printing | Industry leaders are adopting DTF technology, enhancing services for businesses of all sizes with quick turnarounds and no minimum orders. |

| Enhanced Quality and Durability | DTF transfers produce high-quality, vibrant, and durable prints that improve brand reputation by satisfying customer quality demands. |

| Accessibility for Small Businesses | No minimum order requirements make DTF printing accessible for small businesses, allowing them to compete in the custom apparel market. |

| Quick Turnaround Times | DTF transfers enable businesses to fulfill orders quickly, aligning with the fast-paced demands of e-commerce customers. |

| Collaboration and Community | Companies are focusing on collaboration and innovation, enhancing the custom printing ecosystem and supporting creativity. |

| Successful DTF Implementation | Case studies illustrate how the DTF model has benefited businesses like Sam’s DTF Transfers and DTFPrinter, enhancing both service and product offerings. |

Summary

DTF Transfers are revolutionizing the custom printing industry by providing a flexible, efficient, and high-quality solution for businesses of all sizes. As technology advances, DTF transfers not only meet the growing demand for personalized products but also empower small businesses to compete effectively in a bustling marketplace. The versatility, quick turnaround times, and exceptional print quality of DTF technologies ensure they remain at the forefront of industry innovations, setting new standards for custom apparel production. The future of custom printing looks promising, with DTF transfers leading the charge toward a more creative and accessible landscape.