DTF transfers, or Direct to Film transfers, have transformed the landscape of fabric printing by offering an innovative approach that combines quality and efficiency. This groundbreaking technique employs DTF printing, allowing vibrant designs to be easily transferred onto various textiles, which is ideal for custom apparel and decorative merchandise. With the right DTF printing equipment and a solid understanding of the DTF transfer process, users can achieve stunning results that captivate customers. In this article, we’ll explore best practices for DTF, offering tips and insights that will help you master these dynamic printing techniques. Unlocking the full potential of DTF transfers means stepping into a world of creative possibilities that can significantly enhance your branding and merchandising efforts.

Direct to Film printing, often referred to as DTF or film transfer printing, represents a significant advancement in graphic application on fabrics. This method utilizes a specialized film to print designs, providing versatility across different material types, including cotton and blends. The DTF transfer method not only simplifies the printing process but also opens up avenues for creative expression in merchandise creation. By understanding various DTF printing techniques and investing in high-quality DTF printing equipment, businesses can greatly benefit from increased efficiency and superior product output. As we delve deeper into this topic, prepare to discover the intricacies of DTF and how it can elevate your printing projects.

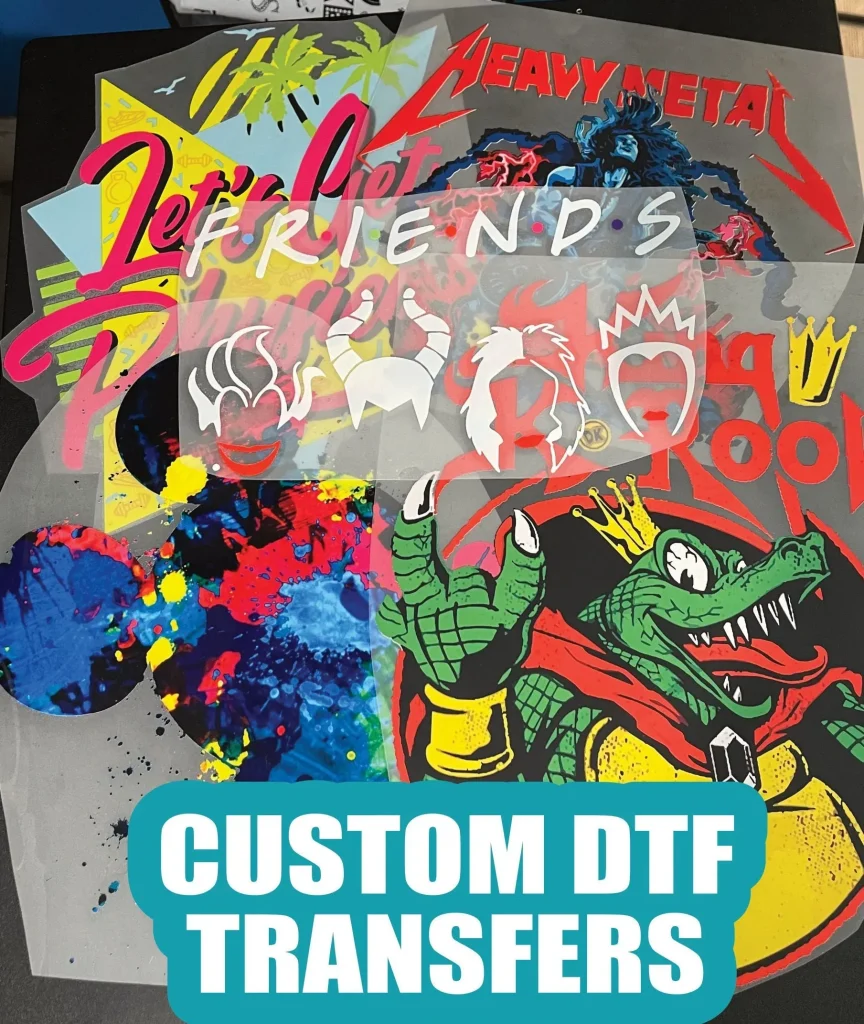

Exploring the DTF Printing Techniques

DTF printing techniques have gained popularity for their ability to produce vibrant, durable designs that seamlessly adhere to fabrics. By utilizing specialized printing processes, these techniques enable designers to transfer intricate graphics onto a variety of materials, ranging from cotton t-shirts to polyester sportswear. This versatility is not only beneficial for small businesses looking to create custom apparel but also for large manufacturers aiming to streamline their production process.

One crucial aspect of mastering DTF printing techniques is understanding the importance of quality materials. High-quality printers that are specifically designed for DTF printing, along with the right transfer films and powders, can significantly enhance the final product. Additionally, adjusting printing settings and ensuring that designs are optimized for transfer can lead to improved outcomes, reducing the chances of flaws or misprints.

The DTF Transfer Process: Step-by-Step Guide

Understanding the DTF transfer process is essential for achieving professional results. The initial step involves preparing your design using graphic software, ensuring that it meets the correct dimensions and resolutions. Once the design is ready, you will print it onto the transfer film using a DTF printer, ensuring that the ink adheres well to the film. It’s crucial to work quickly in this phase, as the wet ink needs to be coated with DTF powder before it has a chance to dry.

Following the application of DTF powder, the next stage is to cure the design—this involves melting the powder onto the film using a heat gun or curing oven to effectively create an adhesive layer. Finally, positioning the film on the fabric and using a heat press to fuse the design is vital. Maintaining the right temperature and pressure during this process ensures that the design bonds well to the material, yielding a final product that is both vibrant and durable.

Essential Equipment for Successful DTF Printing

To embark on a successful DTF printing journey, investing in the right equipment is crucial. A quality DTF printer that utilizes water-based inks is essential, as it delivers vibrant colors and long-lasting designs. Additionally, selecting the appropriate transfer film and adhesive powder specifically designed for DTF printing can make a significant difference in the transfer’s success. This means less trial and error, saving both time and resources in the long run.

Moreover, having a reliable heat press that offers adjustable pressure and temperature settings is vital. The accuracy of these settings can drastically affect the outcome of the transfer, ensuring that the design adheres properly to the garment. Regularly maintaining your equipment, such as cleaning your printer and heat press, is also essential to prevent any build-up that could impact the quality of your prints.

Best Practices for DTF Transfers

Following best practices for DTF transfers can streamline the process and yield higher quality results. First and foremost, proper image preparation is critical; this involves using graphic design software to create designs that are both visually appealing and correctly sized for your printing needs. Additionally, experimenting with different print settings on your DTF printer can help you find the optimal output quality.

Moreover, ensuring that the fabric surface is clean and lint-free before applying the transfer can help achieve a smooth finish. Always follow manufacturer guidelines regarding temperature and pressing times to prevent damage to the design or the fabric. Taking the time to refine these processes will result in higher-quality products and greater customer satisfaction.

Post-Processing Steps After DTF Transfers

After completing a DTF transfer, engaging in post-processing steps is essential for ensuring the longevity of your designs. Allowing the product to cool down completely before peeling off the transfer film helps secure the print in place. If any areas of the design do not adhere properly, repressing them for an additional few seconds can help reinforce the bond, reducing the risk of peeling in the future.

Maintaining your equipment is equally important post-transfer. Regularly cleaning the heat press and printer will prevent issues like ink build-up which could jeopardize future projects. Additionally, proper storage of transfer films and adhesive powders in a cool, dry place is essential to preserve their quality and effectiveness. Maintaining awareness of these factors will enhance the durability and appeal of your DTF printed products.

Innovating in DTF Printing: Experimentation and Creativity

One of the most exciting opportunities within DTF printing is the ability to experiment with designs and materials. Designers are encouraged to explore various fabric blends, as they can yield unique effects and textures that enhance the overall appeal of the printed item. This experimentation can lead to discovering new and exciting products that attract more customers to your brand.

Moreover, creativity is key in differentiating your DTF products from competitors. Utilizing different design styles and finishes can take your custom items to the next level. Whether it’s adding metallic foils, custom coatings, or experimenting with layering techniques, the possibilities are endless. Engaging with fellow DTF printing enthusiasts can provide fresh ideas and inspiration for your next project.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve printing designs onto a special film that can then be transferred onto fabric. This process allows for vibrant and durable prints on various materials, including cotton and polyester. The printed film is combined with an adhesive powder and heat pressed onto the fabric, making it a flexible solution for custom apparel.

What equipment do I need for DTF printing?

To effectively utilize DTF printing techniques, you’ll need a specialized DTF printer, transfer films meant for DTF use, a heat press with adjustable settings, and DTF powder adhesive. This equipment ensures high-quality outputs and successful transfers on fabrics, making your projects stand out.

What are the best practices for the DTF transfer process?

Optimal best practices for DTF transfers include image preparation in graphic design software, using high-quality print settings on your DTF printer, and ensuring accurate application of DTF powder during the transfer process. Additionally, proper cooling and repressing techniques enhance the durability of the prints on fabric.

Can I use DTF printing for various fabric types?

Yes, DTF printing is versatile and can be used on a range of fabric types, including cotton, polyester, and blends. Experimenting with different materials can yield unique results, as each fabric absorbs inks differently, affecting the final appearance of your transfers.

How do I maintain my DTF printing equipment?

Regular maintenance of your DTF printing equipment is crucial for maintaining print quality. This includes cleaning your printer and heat press often to remove dust and debris, and storing transfer films and powders in a cool, dry place to prevent moisture damage, which can impact their effectiveness.

What are some innovative techniques to experiment with in DTF transfers?

In DTF transfers, consider experimenting with various fabric blends, different styles of designs, and unique coating techniques after transfers. These experiments can create truly eye-catching and personalized products, helping your custom items to stand out in a competitive market.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers, or Direct to Film transfers, provide a modern solution for printing graphics on fabrics, accommodating various business sizes. |

| Essential Equipment | Important tools include a DTF printer, transfer film, heat press, and DTF powder. |

| Preparing Images | Images should be designed in appropriate resolution and kept simple for best transfer quality. |

| Transfer Process | Steps include printing, sprinkling DTF powder, heating, pressing, and peeling for a successful transfer. |

| Post-Processing | Cooling and repressing designs as needed ensures quality and adherence. |

| Experimentation | Trying different fabrics, designs, and coatings allows for unique results and innovation. |

Summary

DTF transfers are revolutionizing fabric printing by offering a robust and flexible solution for both small and large businesses. Understanding the nuances of DTF transfers is crucial for achieving outstanding print quality and promoting successful creation processes. By investing in the right tools, preparing images carefully, adhering to the correct transfer techniques, and allowing for experimentation, practitioners can unlock the full potential of DTF transfers. The adaptability of this method supports a diverse range of applications, making it an invaluable asset in the world of print-on-demand merchandise.