In the ever-evolving landscape of custom apparel and product printing, **DTF transfers** (Direct to Film transfers) have quickly become a game-changer. This innovative printing technique allows you to create vibrant and durable designs that can be easily applied to a wide range of materials, including cotton and polyester. Unlike traditional methods such as screen printing and sublimation printing, DTF transfers offer unparalleled versatility, making them an attractive choice for crafters and businesses alike. With the ability to achieve intricate and detailed images, DTF printing is rapidly gaining traction among enthusiasts seeking high-quality, professional results. In this blog, we’ll dive deeper into the benefits of DTF transfers compared to other printing methods, helping you determine the best fit for your creative projects.

Also referred to as Direct to Film printing, DTF transfers have entered the printing arena as a versatile alternative to more conventional techniques like screen printing and heat transfer vinyl (HTV). This modern approach facilitates the transfer of detailed artwork onto numerous fabric types, offering a greater scope than that seen with traditional sublimation printing—a method primarily suited for polyester materials. With a focus on achieving high-quality graphics and fast turnaround times, DTF has carved out a niche in the custom printing market. Whether you’re a budding entrepreneur or an experienced crafter, understanding the various applications and advantages of DTF technology may enhance your production capabilities and inspire creativity in your projects. Join us as we explore the nuances of DTF alongside other popular printing techniques.

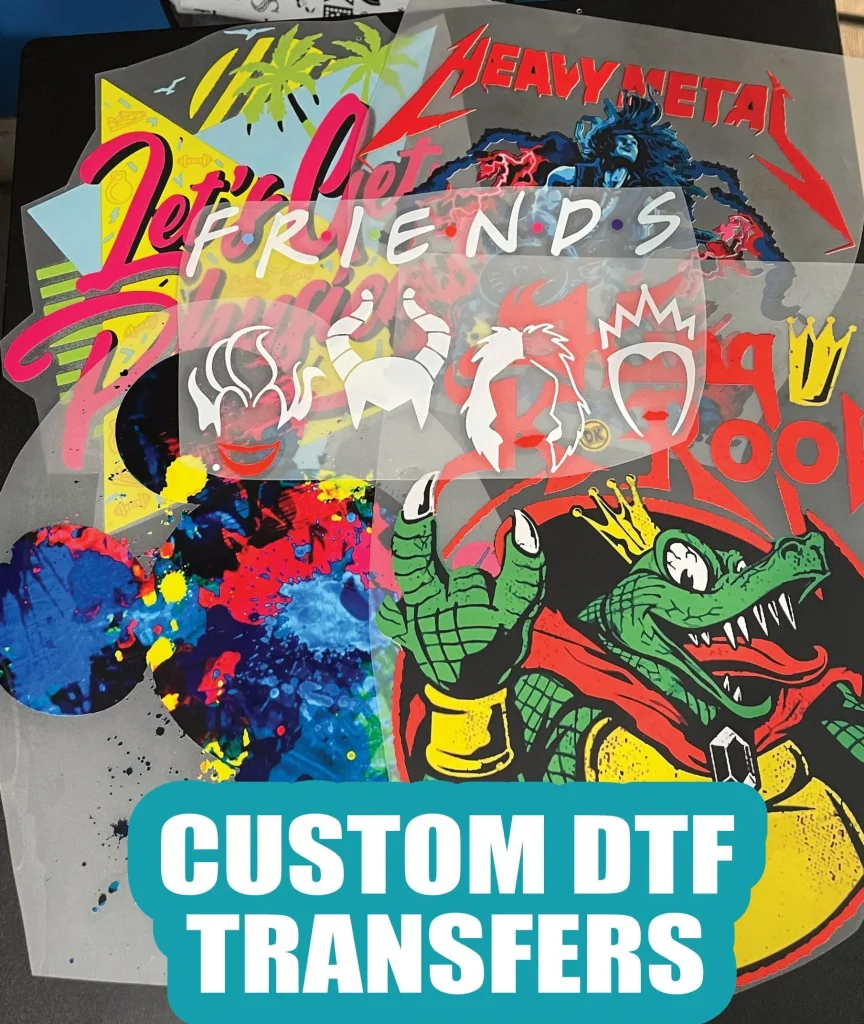

The Benefits of DTF Transfers

DTF transfers have revolutionized the printing industry with their unique advantages. One of the primary benefits is their compatibility with a wide range of fabrics, including cotton, polyester, and blends. This versatility allows businesses to cater to various customer preferences, providing high-quality prints regardless of the material type. Furthermore, the simplicity of DTF printing means that less specialized knowledge is required compared to other methods, making it accessible for beginners and seasoned printers alike.

Another significant advantage of DTF transfers is the efficiency they bring to production. With lower temperature settings, the printing process is not only faster but also results in less wear on printing equipment. The ease of applying DTF transfers means that crafters can quickly produce multiple items without compromising on quality. This can be a game-changer for small businesses looking to scale operations without incurring additional costs.

DTF Printing vs. Screen Printing: A Comparative Analysis

When choosing between DTF printing and screen printing, several key differences come into play. Screen printing is known for its durability and vivid color reproduction, especially for large orders. However, it often requires a significant investment in setup and is less flexible in terms of the design process. In contrast, DTF printing allows for greater creative freedom, as it can handle intricate designs and image details that would be difficult to reproduce with screen printing technology.

Moreover, the production speed is another crucial consideration. DTF printing typically requires shorter setup times and can accommodate rapid design changes, making it ideal for custom orders that demand quick turnaround times. For businesses seeking to fulfill bulk orders, traditional screen printing may offer initial cost advantages but may lack the agility that DTF brings to the table. This flexibility is particularly appealing to modern businesses that need to adapt to changing consumer needs.

Sublimation vs. DTF Printing: Choosing the Right Method

The debate between sublimation and DTF printing often centers on the desired print quality and material compatibility. Sublimation is perfect for producing vibrant, long-lasting prints on polyester fabrics, making it a favorite for sportswear and promotional items. However, it falls short when dealing with cotton and other blend fabrics, where DTF excels. The ability of DTF printing to adhere to multiple fabric types means it offers more options for creative design, a factor that many businesses are looking for today.

Another important aspect to consider is the level of technical expertise required for each method. Sublimation printing generally involves a steeper learning curve, particularly regarding software and equipment setup. DTF printing, on the other hand, is more user-friendly, especially for those new to the crafting scene. This ease of use allows crafters to focus on creativity and personalization without being bogged down by complex processes.

Advancements in DTF Technology

Recent advancements in DTF technology have made significant strides in improving transfer quality and efficiency. Innovations from leading companies have led to the development of more reliable ink formulations and press techniques, resulting in sharper images and greater vibrancy. These advancements directly impact the end product, giving customers high-quality prints that maintain their appearance over time.

Additionally, these technological improvements have streamlined the production process, allowing businesses to keep up with increasing demand without sacrificing quality. New press machines specifically designed for DTF printing have emerged, making it easier for businesses to adopt this method as part of their printing operations. As technology continues to advance, the potential for DTF transfers to incorporate even more complex designs and applications grows, solidifying their position in the market.

Screen Printing vs. DTF Transfers for Bulk Orders

When it comes to bulk orders, screen printing has been the traditional choice for many businesses due to its cost-efficiency in large runs. Screen printing allows for high volume outputs with consistent quality; however, it typically requires a higher initial investment in setup and materials. DTF transfers present a compelling alternative by providing decent output quality without the lengthy setup procedures associated with screen printing.

Another critical factor is the detail and versatility of designs. DTF printing allows for finer detail in designs; intricate patterns or photographic images can be replicated more easily compared to traditional screen printing. This means businesses can meet varied customer demands effectively, producing everything from simple logos to complex artwork on various materials. As a result, DTF transfers are gradually emerging as a preferred option for smaller to medium-scale runs where flexibility and creativity are essential.

Making the Right Decision: DTF or Other Techniques?

The decision on whether to use DTF printing or other methods ultimately hinges on the specific needs of the project. If a business aims to produce diverse products with varying material types, DTF is an excellent choice. It allows for customization without the significant constraints posed by sublimation or screen printing methods. For projects requiring speed and flexibility, the inherent efficiencies of DTF printing become particularly advantageous.

In contrast, businesses focusing exclusively on high-quality prints for polyester materials may still lean towards sublimation due to its unmatched vibrancy on that specific fabric. Each printing technique has its own set of strengths, and understanding the specific requirements of the final product will help guide the choice between DTF transfers, sublimation, and screen printing methodologies.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that is then transferred to fabric using heat. This method allows for high-quality, vibrant images on various materials including cotton and blends, offering flexibility over traditional methods.

How does DTF printing compare to sublimation printing?

DTF printing differs from sublimation in that it can be applied to a wider range of fabrics, including cotton, whereas sublimation is primarily used for polyester. DTF requires lower temperatures and shorter pressing times, making it easier for beginners and enhancing productivity.

What are the advantages of DTF transfers over screen printing?

DTF transfers offer versatility and quicker setup compared to screen printing, which can be costly and time-intensive for smaller runs. DTF allows for intricate designs and is ideal for one-off custom prints, making it suitable for both crafters and small businesses.

Are DTF transfers suitable for intricate designs?

Yes, DTF transfers are highly capable of handling intricate designs thanks to advancements in technology. They can produce detailed images with vibrant colors, making them an excellent choice for custom apparel that requires precision and creativity.

Can I use DTF transfers on all types of fabrics?

DTF transfers are versatile and can be used on a wide variety of fabrics, including cotton, blends, and even some synthetics. This makes them a great option for custom projects that require flexibility in material choices.

What makes DTF printing easier than other custom transfer methods?

DTF printing is easier due to its straightforward process, requiring lower heat and less specialized equipment compared to sublimation. This accessibility makes DTF a favored choice for both beginners and professionals looking to streamline their production.

| Aspect | DTF Transfers | Sublimation | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Material Compatibility | Works on a variety of fabrics (including cotton) | Best for polyester fabrics | Good for large orders and diverse fabrics | Limited fabric choices, best for simpler designs |

| Temperature Settings | Requires lower temperatures (about 330°F) | High heat required (385°F to 400°F) | Varies, but setup can be lengthy | Typically lower, but may vary by design |

| Ease of Use | User-friendly and quick to learn | Steeper learning curve with software requirements | Ideal for bulk production but requires more setup | Easy for beginners, but limited design capability |

| Design Quality | Improving vibrancy and durability, good for intricate designs | Known for its bright colors; works well for specific applications | Durable but limited to simpler prints | Good for colorful designs but struggles with quality like photos |

| Best Use Case | Versatile for various projects and fabrics | Best for vibrant, permanent designs on polyester | Best suited for large orders and bulk needs | Great for individual projects; not for detailed imagery |

Summary

DTF Transfers have emerged as a game changer in the realm of printing techniques, especially for those seeking versatility and ease of use. With their ability to adhere to multiple fabric types, lower temperature requirements, and ongoing improvements in transfer quality, DTF transfers offer a unique advantage over traditional methods such as sublimation, screen printing, and heat transfer vinyl. As the printing landscape evolves, embracing DTF can redefine your printing endeavors, enhancing both efficiency and creativity in custom apparel and product printing. Whether you’re a business owner or a crafting hobbyist, the advantages of DTF transfers make it a compelling choice for all your printing needs.